Why Buy Local?

Buying local is a HUGE win for all sides.

- You are getting fresh meat.

- You know who raised it and you can ask how they raised it and fed it. Often you can see them being raised.

- The taste. You will never go back to commercial meat once you have tasted local meat.

- The supply chain. it takes well over 40+ local families to raise livestock. We need: hay and straw farmers, nutritionists, local State agents (USDS, FSA, Extentionists), local bankers, feed mill workers, farmers that supply the feed mills, truckers that haul feed and livestock, sale barns, veterinarians, vendors that sell our prouducts, farm market staff, bookkeepers and CPAs, tractor and implement sales and repair, auto and truck repair, seed and fertilizer vendors and custom services (planting, fertilizing), electricians and plumbers, graphoc designers, surveyors, sawmills and many more locals help us get food to you.

- If/when you buy commercial meat – the producer (Tyson/Smithfield etc) owns the animals, owns the trucks, owns the feed supply – the only local getting paid (and barely making it) is the grower. Sure they have workers on staff packing meat for a few bucks an hour but that’s about it. They pack and truck the meat to the store – or ship it from overseas. There sure are a lot of travel miles on store bought meat.

- Commercial meat has many disadvantages – it may be fed additives to make it leaner (Pay lean for pork – legal in the USA but banned everywhere else); it might be from overseas – there are no laws that require labeling for country of origin anymore, there is no to little local supply chain. The conditions may be filthy, the death rate of animals that get sick is astounding – local farmers CARE.

About Buying Lamb, Pork and Beef Bulk

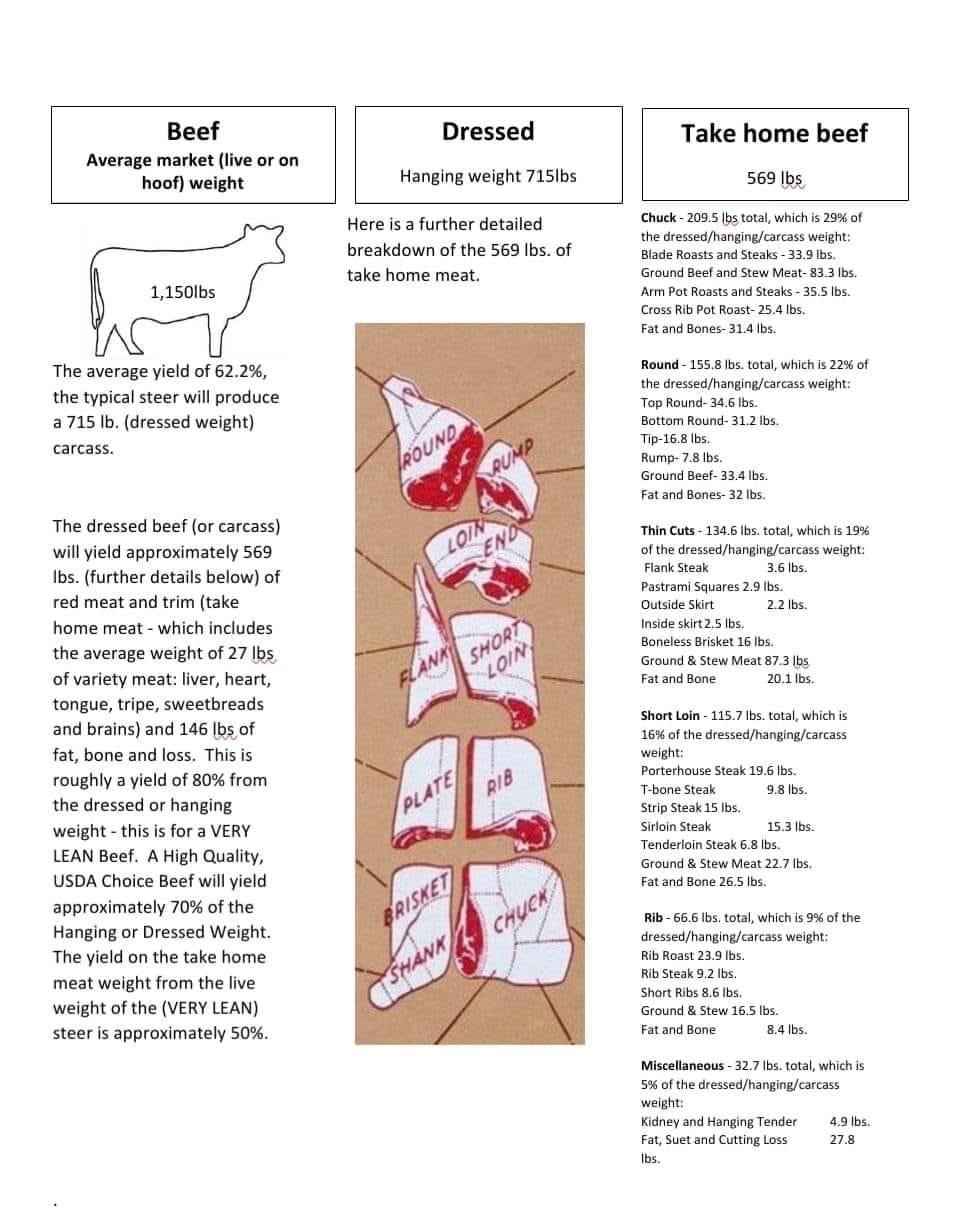

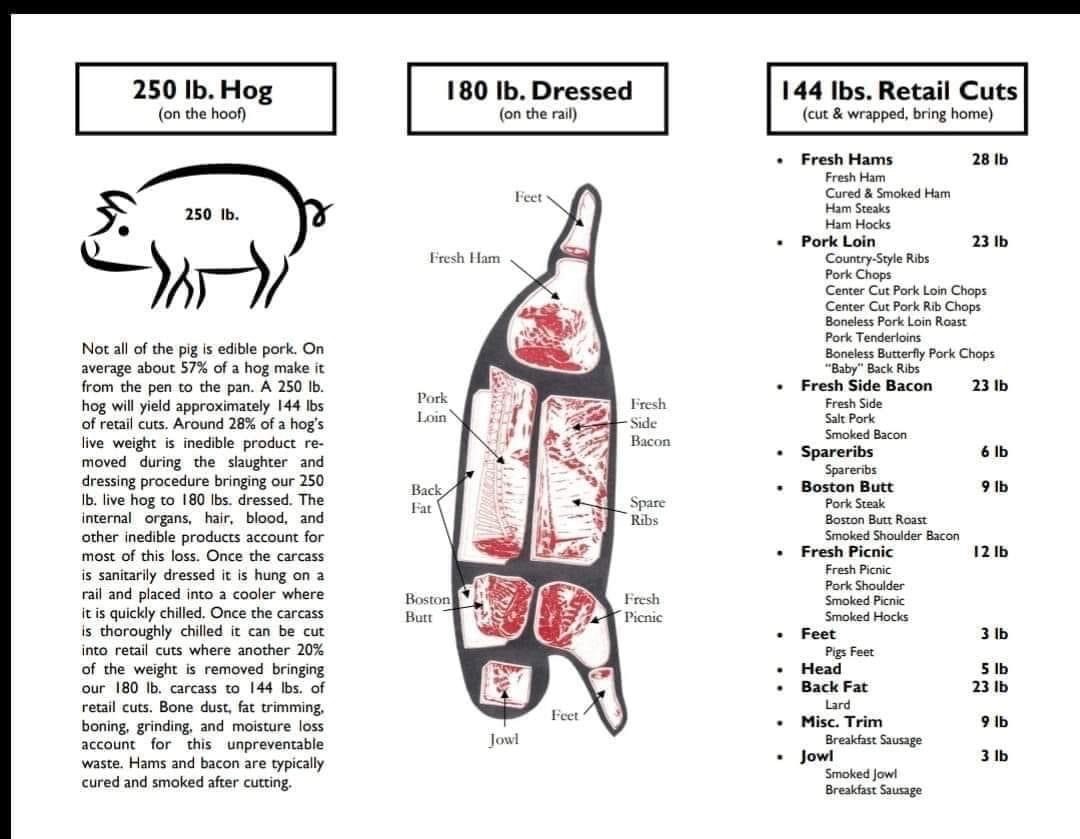

Lamb, pork and beef are generally sold either live weight (on the hoof) or hanging weight (on the rail or “dressed”). From live weight to on the rail you lose about 28% to 50% of your weight. From the rail to your plate you will lose bone (if boneless cuts are chosen), fat, inedible scraps and the neck. This will also trim anywhere from 15% to 50% off of your hanging/rail weight.

The best way to get the biggest bang for your buck is to request everything back – it is ALL usable. We use suet for birds, offal (organs) for cooked dog food (many feed it raw), we smoke the bones for dog bones or use it for bone broth or demi glace. Jowl and hocks are great smoked for soups and beans. Beef tongue is popular in most cultures. Lard is more healthy than butter and it has a much higher smoking temperature plus it doesn’t have to be refrigerated. There are uses for every part of your purchase. Do not waste it.

Let’s do some quick examples of weight:

|

Live Weight (On the hoof) for a whole animal (Example only) |

Rail/Hanging Weight | Hanging Weight for a Side/Half |

ESTIMATED Take Home/On the Plate (lamb has much less loss) for Half /Side(assume bone in and boneless with no take home bones or offal) |

For a 1/4 Divide the side by 50% | |

| Beef | 1,400 lbs | 725 lbs | 362 lb | 235 lbs @ 35% loss | 117 lbs |

| Pork | 350 lbs | 200 lbs | 100 lb | 70 lbs @ 30% loss | 35 lbs |

| Lamb/Goat | 90 lbs | 45 lbs | 23 lbs | 20 @ 13% loss | 10 lbs |

The next tab will detail ordering.

How Does Ordering Work?

Once you have made the life changing decision to order local, humanely raised meat what do you do? Whether it is from Fox Crossing Farms or another local farm, the process will be similar.

- Place a deposit. The deposit reserves your spot in line. A farmer has a lot of work to get livestock into processing and he or she can’t afford to be stuck with an unpaid bill. So, most farms will require a deposit. Make sure you get an INVOICE and a paid receipt.

- After a deposit is placed and cleared you will get a link to submit your cutting order. The next tab will talk about cutting orders. On the cut sheet you will put your contact information so the processor can call you with questions or, if no questions, to pick up your finished product.

- The farmer will receive the hanging weight from the processor. This will be the actual hanging weight/rail weight of your portion. At this point you will know exactly how much to pay the farmer. He/she should send an invoice or notice of some sort for the remainder due. The deposit will be placed against the total cost of the meat for the farmer’s portion.

- Here is an example (not your actual numbers):

Item Deposit Price Per Pound Hanging Weight Total Cost Amount Due After Deposit Beef Split Side (1/4) $500.00 $3.50 174 lbs $3.50 x 174 lbs = $609 $609-$500 = $109 Due to release meat - You will pay the farmer the remainder. The farmer then tells the processor that your meat can be released to you .

- You go to the processor to pick up the meat AND pay them for any costs that were incurred for smoking, tenderizing, curing, slicing, etc. Every processor will have their own fees. Most farmers will not include slaughter and processing costs in their price. Those charges may range from $50 to $100 for slaughter and $0.75 to $1.00 per pound for processing. Make sure you know what you are paying for in advance! Those fees are strictly charged by the processor.

The next tab will get into cuts and details on cuts.

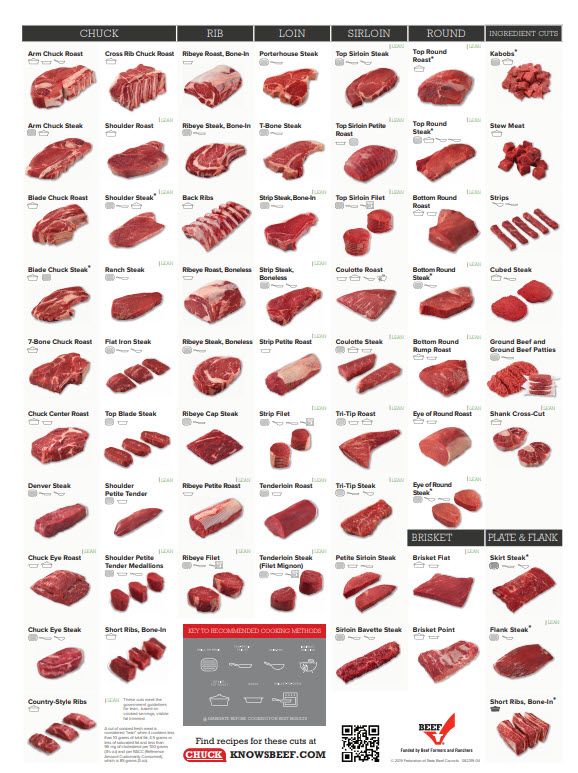

What Cuts Do I Get?

With custom processing you get a huge variety of cuts (see the detailed lamb, beef and pork tabs below). The options are endless but there are common options and “cut sheets” walk you through them.

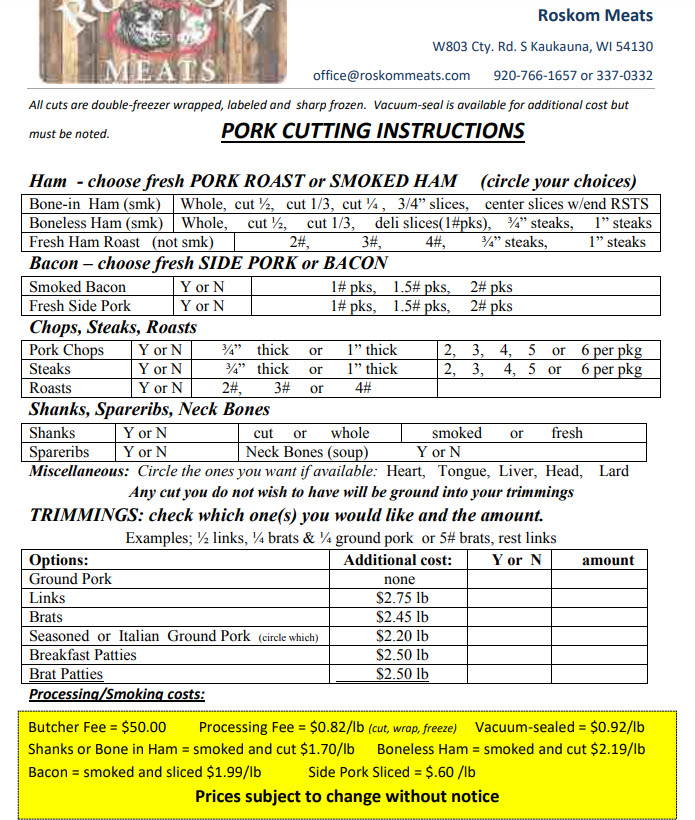

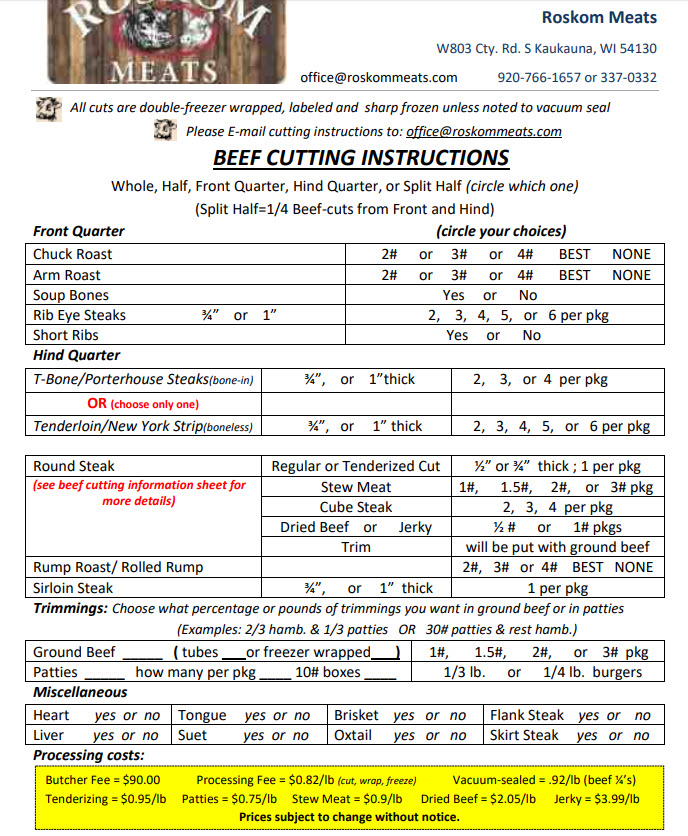

Here are sample cut sheets from our favorite processor – Roskom Meats in Kaukauna. We strictly use Roskom because of their service, price and seasonings/smoking. Every processor may use different seasonings – so sometimes it might be worth buying some sausage, bacon, brats or ham from them to try before you have an order processed.

Please do not use these cut sheets – if you order through us an interactive link will be sent to you. We or the processor will be happy to walk you through filling out a cut sheet for our orders.

There are some tips for cut sheets – you don’t know how many pounds of something you are getting so you can say 1/4 of the ground each for breakfast sausage, maple breakfast links, brats and unseasoned ground. For hams – you can say give me 4# end hams and the center sliced into 1/2″ slices.

Please note: Roskom now has maple breakfast seasoning – it is sweeter than the traditional sage seasoning but you must request it specifically.

More About Processing/Ordering – BEEF

More About Processing/Ordering – PORK

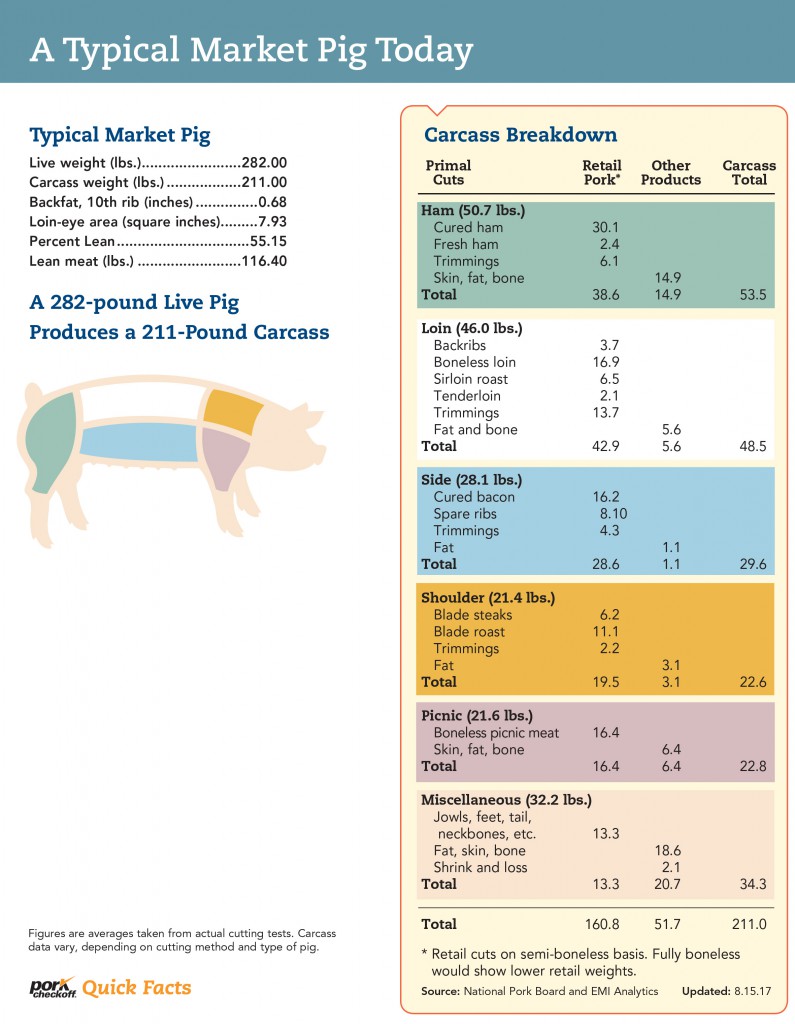

Here is some information on what cuts come from a side of pork .

More About Processing/Ordering – LAMB

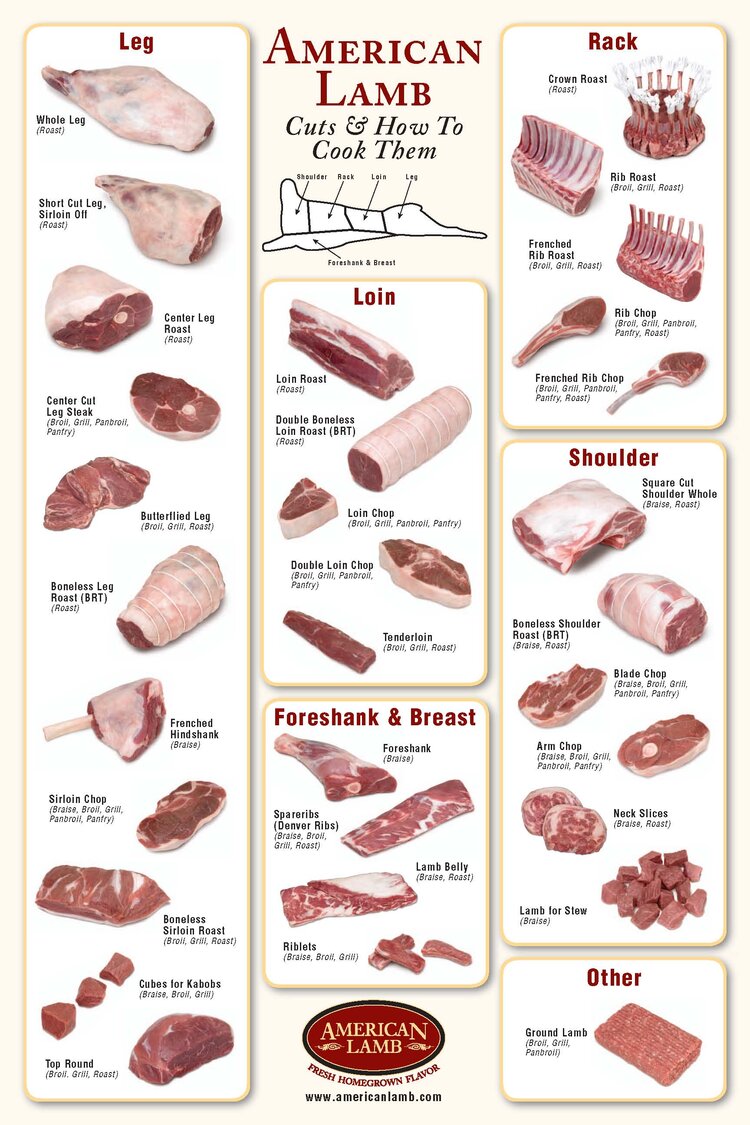

Here is a breakdown of what cuts come from a lamb/goat. Be adventurous and try them all – the best cuts are NOT what the store sells I guarantee it.

Inspection and Processors

In Wisconsin processors (places that slaughter) and butchers (break the carcass down into cuts) can be inspected or uninspected. We’ll take a look at three scenarios.

USDA Federal Inspection: USDA inspection is the highest inspection level in the US. Meat that is sold in stores within the state it was processed in must be inspected – but only meat that crossed state lines must be USDA inspected

State Inspection (DATCP): ALL meat for resale must be inspected to the state minimum. Both USDA and DATCP inspectors place blue edible ink stamps on the carcass to indicate that the animal and carcass have been tested or certified to be consumed.

Custom Uninspected: Uninspected processors (custom processors) work for the buyer only. Farmers can not use a custom processor to resell meat in Wisconsin. There are both fixed and mobile processors in Wisconsin. Mobile units come to your farm or place and process/slaughter there. They each may offer different services – some may butcher and some may not. Some may hang your meat and cool it and others won’t.

The Wisconsin DATCP keeps lists of licensed processors. Both inspected and uninspected. Click on these links to find processors. (If these links break please email us for correction)

DATCP State Inspected Processors

Mobile Processors – Mostly custom but ask to find out.